HD8813 WS2813 Pixel LED Chip

Product Specifications:

| Product Name | HD8813 LED Chip |

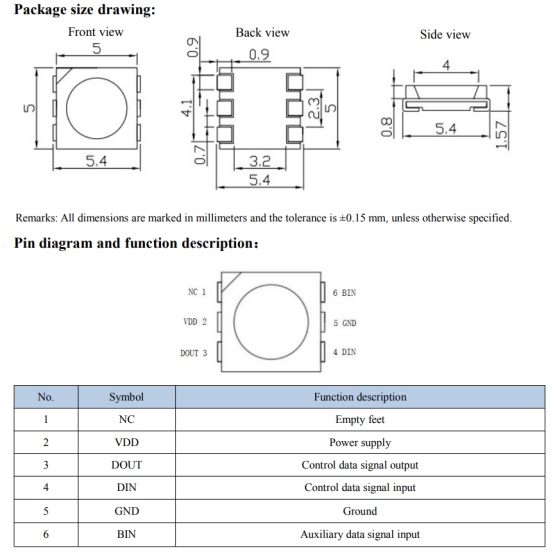

| LED type | 5050 SMD LED |

| IC type | HD8813 |

| Emitting Color | Digital RGB |

| Voltage | DC5V |

| Gray Scale | 256 |

| Moisture-proof grade | LEVEL5a |

| Certification: | CE, EMC, FCC, LVD, RoHS |

Application:

LED full-color luminous character string light, LED full-color soft and hard light bar, LED point light source, LED pixel screen, LED special-shaped screen, LED full-color module, car lights, shoe lights, toys, audio, home appliances, and various electronics product.

Detail of LED Chip

A kind of solid-state semiconductor device, the heart of LED is a semiconductor chip, one end of the chip is attached to a bracket, one end is the negative pole, the other end is connected to the positive pole of the power supply, so that the whole chip is encapsulated by epoxy resin.

Also known as LED light-emitting chip, it is the core component of LED lamp, also known as p-n junction. Its main function is to convert electric energy into light energy, and the main material of the chip is monocrystalline silicon. Semiconductor chip is composed of two parts, one is p-type semiconductor, in which the hole is dominant, the other is n-type semiconductor, in which the electron is dominant. But when the two semiconductors are connected, a p-n junction is formed between them. When the current acts on the chip through the wire, the electrons will be pushed to the p region. In the p region, the electrons will compound with the holes, and then emit energy in the form of photons. This is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the p-n junction.

The traditional LED chip adopts the front mounting structure, which is usually coated with a layer of epoxy resin and sapphire as the substrate. On the one hand, due to the poor thermal conductivity of sapphire, the heat generated by the active layer can not be released in time, and the sapphire substrate will absorb the light from the active region, even adding a metal reflector can not completely solve the problem of absorption; On the other hand, due to the poor thermal conductivity of epoxy resin, the heat can only be dissipated by the pins under the chip. Therefore, both the front and the back cause heat dissipation problems, which affect the performance and reliability of the device. In view of this, led flip chip welding technology came into being.

FAQ

Q: Could you please send me the free sample, so that I could see and check its quality?

A:Yes, we accept sample order, we can ship some free sample for customer to test , but the buyer need to pay the shipping cost.

Q: What certificate you can offer?

A:Usually CE and RoHs,others UL certification we can offer too based on your need.

Q: What payment way you accept?

A:T/T, Paypal, Western union all works to us.

Q: What is your lead time?

A:Usually the goods can be shipped with1 week, the customized led products takes more time according to detailed products.

Q: Does all the products designed by yourself?

A:Yes, our boss is also an engineer and we have more than 10year exprenced engineer team, all the led products designed by ourselves.